Mortise Chains

The term “mortise chains” is often used as a synonym for set, the complete tool made up of a chain, guide bar and sprocket for the production of rectangular, square and trapezoid slots in medium hardness wood.

The set is mounted on mortising machines, which may be stationary or portable.

- The stationary machines are generally of Italian and German manufacture, and have a guide-sprocket centres of 150 mm.

- The portable machines are generally of India manufacture, and have a centres of 70 mm.

However, many other mortising machines with different centres are also in operation.

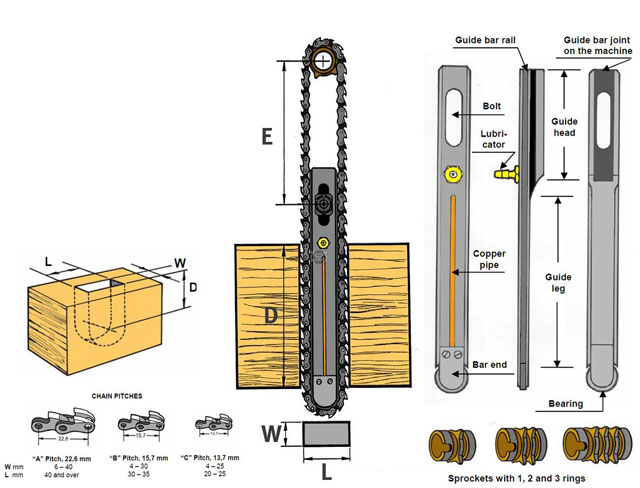

Shark Guide Bars

This is the part of the set on which the chain slides during the penetration of the wood.

It consist of an upper part known as the guide head and a lower part known as a guide leg.

In the rear of the head, is a 13 mm wide slot used for attachment to the mortising machine.

The head contains an elongated 12,7 x 50 mm hole known as the bolt, which performs the dual function of maintaining the chain tension, regulating the height of the guide and attaching this to the screw of the mortising machine with a nut.

Along the guide leg, there is a threaded hole for the fixing of the lubricating oil system, which may be manual (Stauffer) or automatic.

The oil is taken to the bearing in the lower part of the guide from this hole through a copper pipe.

Along the sides of the guide is the guide bar rail, on which the inner link of the chain slides.

The width of the guide bar rail is not the same in all the guides, and depends on the width of the mortise to be obtained.

Each guide bar may be used for one or more chain size, as indicated in the table of “International Standard” below.

The description “12-17” in this table, for example, which is also etched into the guide bar, means that the guide can be used for the mounting of chains with a thickness measurement of 12, 13, 14, 15, 16 and 17.

The Shark guides are of a length that permits the mounting of chains with a standard number of links.

The Shark Chain Pitches

The pitch is the distance between the one pin in a link and the third successive one, as shown in the figure. Shark chains are produced in the following three pitches:

- “A” pitch (22,6 mm or .89″) for mortises of 40 or 50 mm or longer.

Used for routine carpentry work.

- “B” pitch (15,75 mm or .62″) for mortises 30 and 35 mm long.

Used for work requiring high levels of accuracy and precision.

- “C” pitch (13,7 mm or .54″) for mortises 20 and 25 mm long.

Used for extremely precise work.

The Shark chains

This is the part of the set with cutting teeth that makes the mortise in the wood. The length of the chains is expressed by the number of links making it up, and depends on the following factors:

- chain pitch;

- length of the guide on which the chain is to be mounted;

- guide bar – sprocket centers of the mortising machine.

The center of the mortising machine is the distance between the mid-line of the sprocket and the mid-line of the locking screw of the guide bar to the machine, as indicated in the figure to the side.

The standard production Shark chains are built to be mounted on guide bars with a preset length, for machines with a centre of 150 mm, and are made up of:

- 36 links for pitch “A”;

- 48 links for pitch “B”;

- 54 links for pitch “C”.

Shark Chain Sprockets

Shark sprockets

The sprocket is the third component part of the set. It is fixed to the motor shaft of the mortising machine and transmits the rotary movement to the chain. The sprockets are produced as follows:

- for “A” pitch with 4 and 5 teeth (mortises 40 and 50 mm long;

- for “B” and “C” pitches with 6 teeth (mortises 35, 30, 25 and 20 mm long).

Applications of Using Mortising Chain

Shark chains can be used for different machining purposes, starting from the classic construction of doors and windows up to the creation of building structures of wood, such as the construction of large architectural complexes, modern homes and beams, the machining of shoe forms and so on.

Its innovative chain cutters allow machining of all types, from milling, notching, and even contouring to boring, and can be used both on CNC machines as well as carpentry tools like the common drill.

Whether on fixed or portable machines, or for industrial to private use, our products feature a wide range of sizes, and we offer the customer the opportunity to request special sizes outside of our standard production.